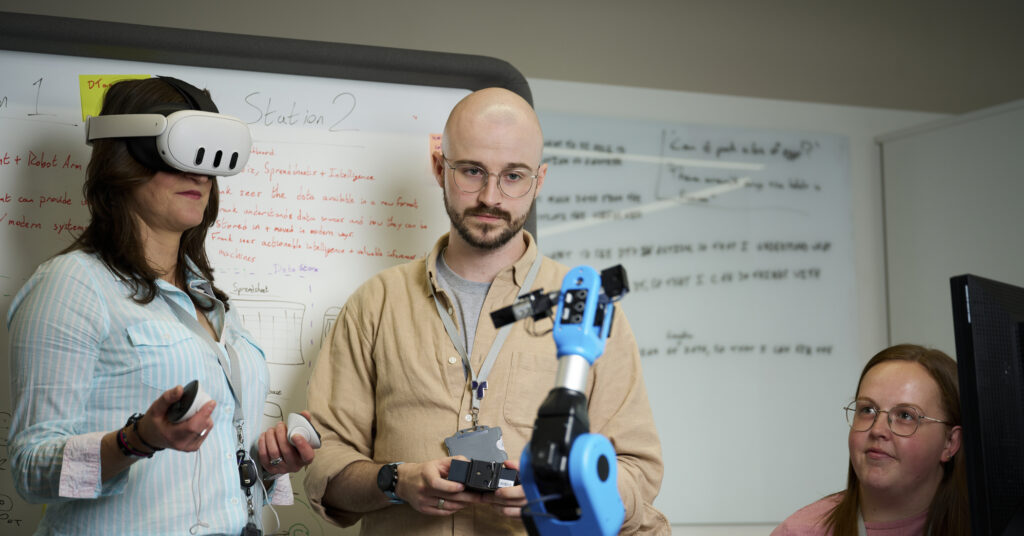

Digital Catapult has named five startups that will join its accelerator programme to improve industrial supply chain resilience in the defence industry and drive the practical application of deep tech innovation to equip the sector to be future ready. The Digital Supply Chain Hub Defence Testbed Accelerator will address secure data sharing challenges to support faster, more agile additive (3D printing) manufacturing across the UK’s defence supply chain and enable participating companies to scale.

The accelerator programme is delivered by Digital Catapult as part of the Made Smarter | Digital Supply Chain Hub alongside the Ministry of Defence (MOD), other major defence manufacturers, and cutting-edge UK-based small businesses. The programme will convene capabilities, with support from the National Composites Centre (NCC) and the Manufacturing Technology Centre (MTC), to unlock new opportunities for the MOD and its partners to securely manage and share manufacturing design data.

As it stands, the UK defence sector faces increasingly long lead times to secure military and defence assets, and fragmented data systems which constrain equipment availability, disrupt supply chains and threaten the UK’s defence and security capabilities. To solve these challenges, the MOD is looking to identify innovative ways to create a federated digital inventory of manufacturing information which will give authorised partners a single and secure view of essential technical data, enabling distributed 3D printing of defence components.

The five participating startups will work on two separate challenges to validate and trial new solutions that explore the applications of deep tech to achieve secure, connected, and responsive defence manufacturing. Dataline Labs, CamyPro and TECHNIA will work to address the Technical Data Packs (TDP)-Digital Inventory Connectors challenge, developing software solutions to securely extract and standardise metadata from Product Lifecycle Management (PLM) systems. Vistory Group and Quaisr will tackle the Federated Digital Inventory challenge to consider the best way to develop a unified, permissioned platform to view and share technical data across the entire supply chain.

Both challenges will bolster industrial supply chain resilience, building on Digital Catapult’s success in this space to date, which has seen 37 Digital Supply Chain Hub projects delivered, and 135 engagements with manufacturing and technology SMEs, which represents a year-on-year increase of 44. Technology companies on the Digital Supply Chain Hub have also secured over £6 million in funding since participating on the programme, reflecting the value of the intervention in enabling companies to commercialise their solutions and scale.