Last month, Digital Catapult hosted a DETC Pit Stop where Mark Chapman, Chief engineer, unveiled the record-breaking Bloodhound Project. Andreas Alexiou, Innovation Manager at Digital Catapult discusses how the organisation is supporting the technologies to make this attempt possible – and how it is also set to turbocharge the British manufacturing industry.

On December 18th, 1898, Gaston de Chasseloup-Laubat made history as the first man to officially hold a mechanised land speed record. Careering across a single kilometre run in his 36 horse-power electric Jeantaud Duc, Gaston reached a heady 39.24mph.

121 years later, Mark Chapman is following in Gaston’s footsteps – except he won’t be popping the champagne until he tops 1,000 mph – 25 times faster. To accomplish this special feat, Bloodhound will draw on around 135,000 horse power in total – that’s more than six times the power of all the Formula 1 cars on a starting grid put together. Massive steps have already been taken in the design and build pr ocess and when the vehicle lines up on its specially created race track at Hakskeen Pan, South Africa, it will reflect the incredible engineering progress that UK manufacturing has made over the past 120 years.

Record-breaking efforts happen through groundbreaking technology

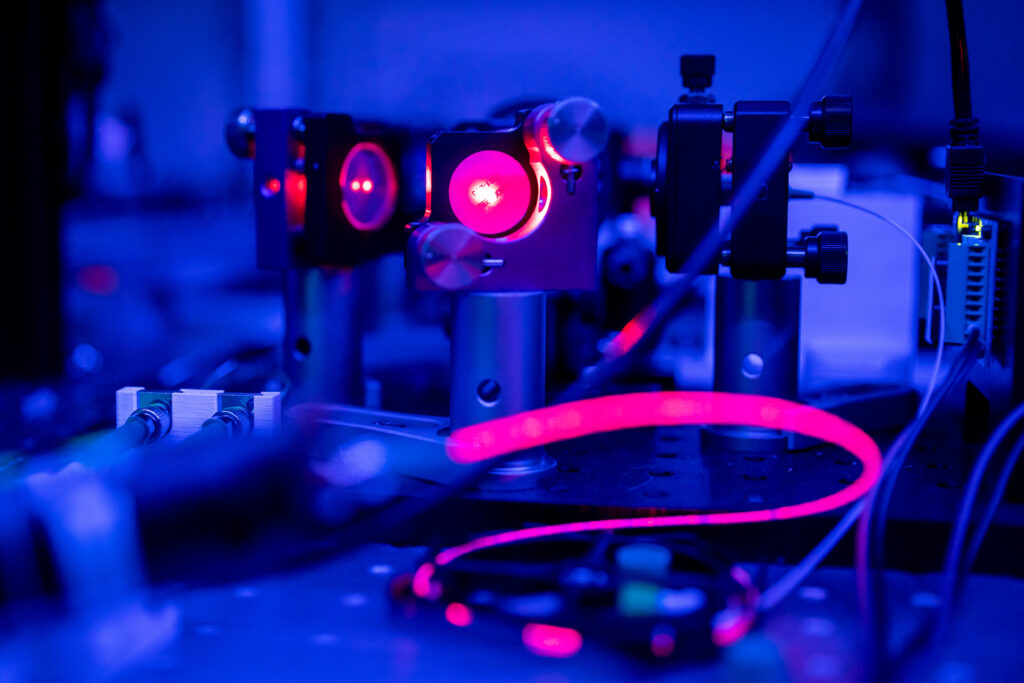

Yet raw power is only half of the story. Since the Bloodhound project’s inception in 2008, over 110-man years of effort have been invested into the design, build and manufacture of the vehicle, with next generation IoT and VR technologies also playing a crucial role.

IoT sensors have been installed on the vehicle, measuring variables such as drag and speed, enabling engineers to make targeted changes to the vehicle’s design and performance without incurring additional build costs. Added to this, 550 further IoT data sensors combined with advanced VR technologies are helping predict how the car will handle when it’s under the control of a human in a real rather than simulated environment.

Inspiring future development

The Bloodhound project is emblematic of Britain’s rich engineering heritage and ongoing endeavour to push boundaries. It demonstrates what can be achieved when innovative technologies are applied and a dogged determination is brought to bear on any manufacturing process.

Luckily there is no shortage of innovative UK tech start-ups ready to provide advanced technical solutions to the challenges faced by traditional industry. But while these companies excel in tenacity and vision, they often lack the business skills or connections to make them a reality. And without the right support, Britain risks losing solutions before they even start to see the light of day.

More than just a helping hand

Such an outcome would be of serious detriment to UK industry and the economy. This is why Digital Catapult drives the early adoption of technologies to solve big challenges in the manufacturing and creative industries, making UK startups and scaleups more competitive and productive and in so doing, grow the country’s economy.

As mentioned earlier, IoT technologies have been instrumental in getting Bloodhound to where it is now. However, crucial to the development of IoT in the UK, is early stage access to LPWAN – the network that many IoT systems run off. There is no national provision for this, but through our Things Connected programme we are establishing an ever-growing sum of regional networks.

These enable the use and development of IoT technologies, helping Britain gain a foothold in this emerging and rapidly expanding global market.

Digital Catapult is also supporting companies in the VR space through our CreativeXR and Augmentor programmes.

Both support early stage immersive companies with CreativeXR focused on helping them unlock the creative potential of immersive content, while Augmentor supports those businesses who are developing innovative and commercially-focused applications of augmented and virtual reality. Gravity Sketch, for example – a tool that allows designers to collaborate and develop 3D models in VR and a member of last year’s Augmentor cohort, has already raised £1.25 million in investment.

Britain’s industry is all ears

While projects like Bloodhound are as rare as they are innovative and daring, they play a pivotal role in demonstrating how new technologies can be applied.

This is why we invited Mark Chapman to one of Digital Catapult’s DETC pit-stops – to help foster the ‘Bloodhound’ attitude in those startups in attendance and discuss how, with the same unwavering focus and tenacity, they could also achieve their goals.

In time, our ambition is that these technologies will be adopted by the leading manufacturers in the development of their own vehicles and services, and that the same technology used in Bloodhound will be used to develop the cars that both you and I drive (although I’d be impressed if they went as fast!).

Get all of the insight behind this exciting project and watch how virtual reality and Internet of Things technology is being used to make it all happen.