Is nanotechnology the future of ‘smart’ manufacturing?

Posted 8 Nov 2022

Nanotechnology and Nanomanufacturing

As discussed in the last instalment of the Smart Nano series, photonics and nanotechnology are closely related and intertwined areas that underpin many technologies which are essential for the functioning of modern society. Nanotechnology involves developing nanomaterials and nanostructures that have dimensions on the order of billionths of metre to realise novel properties that stem from increased surface areas and quantum effects, and can be thought of in terms of nanomanufacturing, nanoimaging/sensing, underpinning nanomaterials and enabled products – respective examples include photolithography, electron microscopy, nanotubes and computer chips. Significantly, nanotechnology is an enabling technology with a wide range of applications, from electronics and energy to medicine and manufacturing.

Uses of Nanomaterials

Nanomaterials, materials with nanoscale dimensions, are commonly incorporated into products to enhance performance and provide novel properties. They are based on a number of different materials, including carbon and metals, possessing many remarkable electrical, mechanical, thermal, chemical and optical properties. Quantum dots, for instance, are employed in displays, with their colour stemming from quantum confinement. Moreover, the significantly larger surface area afforded by nanoparticles compared to bulk materials can be directly exploited, for example in catalytic converters, where they reduce the quantity of metal required.

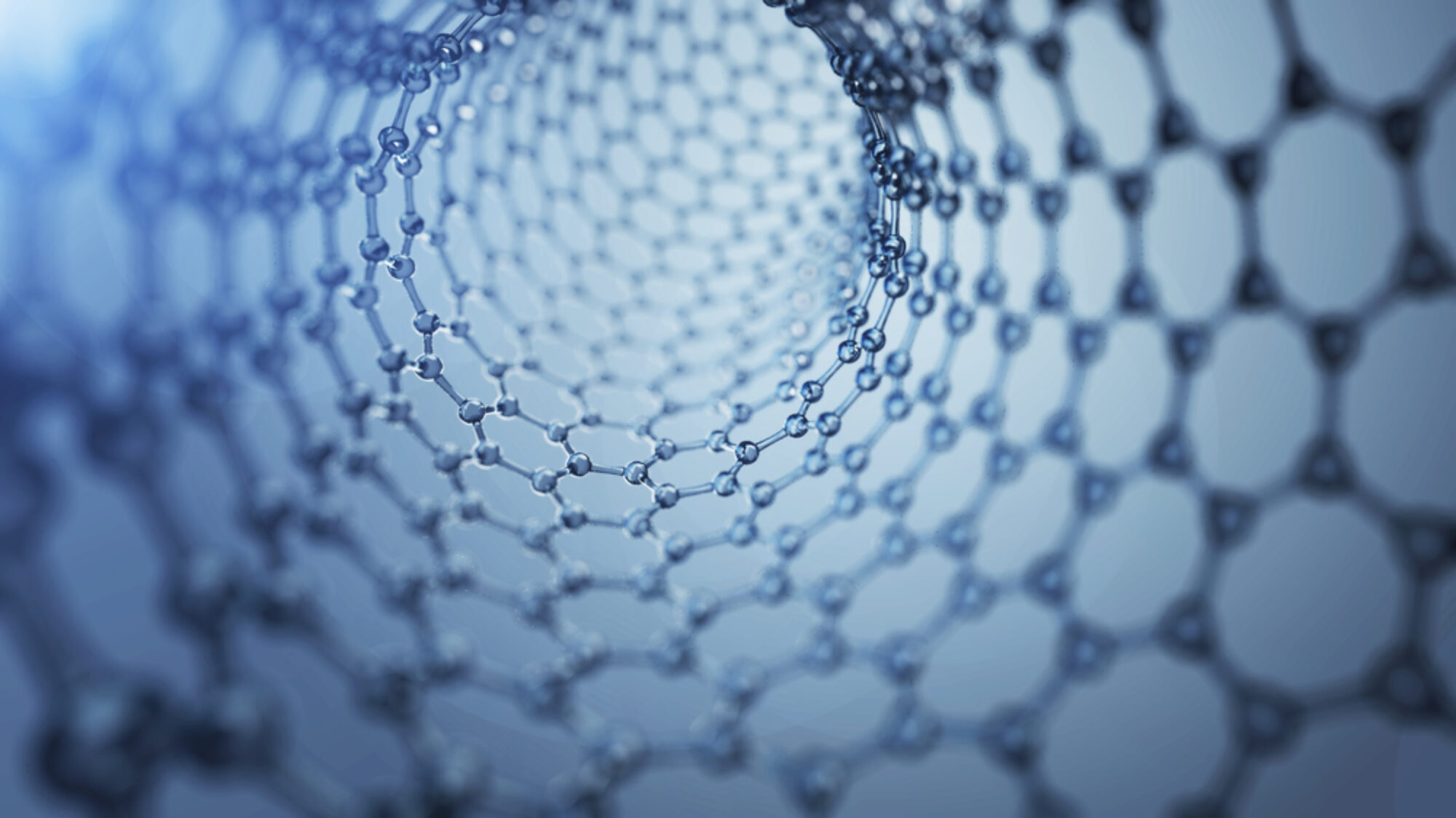

In terms of carbon-based nanomaterials, nanotubes can be incorporated into materials to improve their strength whilst minimising weight. They are already used for sporting goods, such as bike frames and tennis rackets, as well as for automotive composites. In addition, nanotubes may find applications in electronics, permitting flexibility for wearable devices. Graphene, which is composed of a sheet of carbon atoms, is a potentially disruptive material due to its novel properties, including high strength and electrical conductivity, and is part of a family of two-dimensional materials. It is already being used in many products, such as textiles, tires and batteries.

Further illustrations of include commercially available nanomaterials include: nanoparticles incorporated into lubricants to enhance their performance; silver nanoparticles used for keeping food fresh via their antimicrobial properties; nanocoatings for self-cleaning, insulation, scratch-resistance and anti-static packaging; and nanoparticles for targeted drug delivery. Nanomaterials are also important to quantum technologies, such as in the case of fluorescent nanodiamonds and quantum dots for single photon sources.

Nanomanufacturing: building on the nanoscale

Nanomanufacturing refers to high volume production of nanomaterials and nanostructures – this requires specialised techniques, as conventional means of manufacturing do not offer the required resolution. This typically involves the removal of material to produce nanoscale features (top-down) or the building of nanostructures from smaller components (bottom-up). Nanomanufacturing is routinely used in the production of integrated circuits that contain nanoscale features, i.e. photolithography. Another prominent example is nanoimprint lithography, which relies on mechanical deformation to produce nano-features, such as for solar cells.

In terms of bottom-up fabrication, self-assembly entails components arranging themselves without external direction and is a powerful approach to realising nanostructures. An example is colloidal self-assembly, where dispersed nanoparticles are employed to assemble structures. Moreover, the synthesis of nanoparticles themselves may involve bottom-up or top-down approaches, such as chemical or physical methods.

Another means of generating nanostructures without external direction uses DNA itself: DNA-origami relies on folding DNA strands upon which different nanocomponents can be attached. Employing DNA itself as scaffolding permits unique arrangements of nanoparticles to be assembled, such as nanoscale optical components. Producing nanometre-thin films, such as those utilised in semiconductor devices, can be achieved using many techniques, such as thermal evaporation of materials. Other techniques for producing nanostructures include scanning electron beam lithography, which creates a nanopattern that is subsequently processed, and focused ion beam milling, which allows material to be selectively etched.

Imaging, sensing and manipulation on the nanoscale

A variety of tools are available to provide a window on the nanoscale, where conventional optical microscopes cannot provide sufficient resolution, yielding important information on the properties of nanoscale components. For example, scanning probe microscopy and electron microscopy provide nanoscale resolution via scanning a sharp tip or beam of electrons across the surface of a nanomaterial and monitoring the resulting signal, respectively. The specific choice of nanoimaging technique depends upon many factors, such as the required resolution, imaging area, and information to be collected.

Nanosensors, which can incorporate nanomaterials, may provide many advantages over other devices, such as higher sensitivities and lower power consumption. For example, sensors based on nanostructured metal surfaces can enable the detection of single molecules. Incorporating a multitude of nanosensors into a network would also facilitate an Internet of Nano Things, which would immensely benefit smart manufacturing; for instance it could significantly augment the ability to monitor quantities such as equipment temperature and emissions. Another promising avenue for nanotechnology is in the programming of nanoscale objects to carry out specific tasks; nanomachines could play a significant role in medicine, helping to identify and destroy cancer cells.

Nanomanufacturing prowess in Northern Ireland

The Smart Nano NI consortium has considerable expertise in nanomanufacturing: Causeway Sensors develops sensors that rely upon nanostructures, and the Centre for Nanostructured Media at Queen’s University Belfast specialises in development of new approaches to nanostructure development and characterisation. In particular, the metal-based, plasmonic, nanostructures developed within the consortium have a wealth of applications in sensing, energy harvesting and data transmission due to their unique optical properties. Here nanotechnology directly overlaps with photonics – nanophotonics – which will be covered in the next blog post.

Looking ahead

There is a broad range of nanomaterials, nanostructures and nano-enabled devices already used for a diverse range of products and applications – from coatings to computer chips. Looking to the future, many emerging nanotechnologies may prove revolutionary, such as in medicine and energy. The ability to produce nanoscale structures at high volumes will become increasingly important to many sectors as various nanotechnologies mature, and thus nanomanufacturing will continue to play a critical role in developing new products with improved performance and greater functionality.

If you’d like to explore what nanomanufacturing could do for your business, read up on how you could get involved in Digital Catapult’s Smart Manufacturing programme here.