Digital twins – the case for investment

Posted 2 Jun 2023

Unlocking the power of digital twins in the UK…

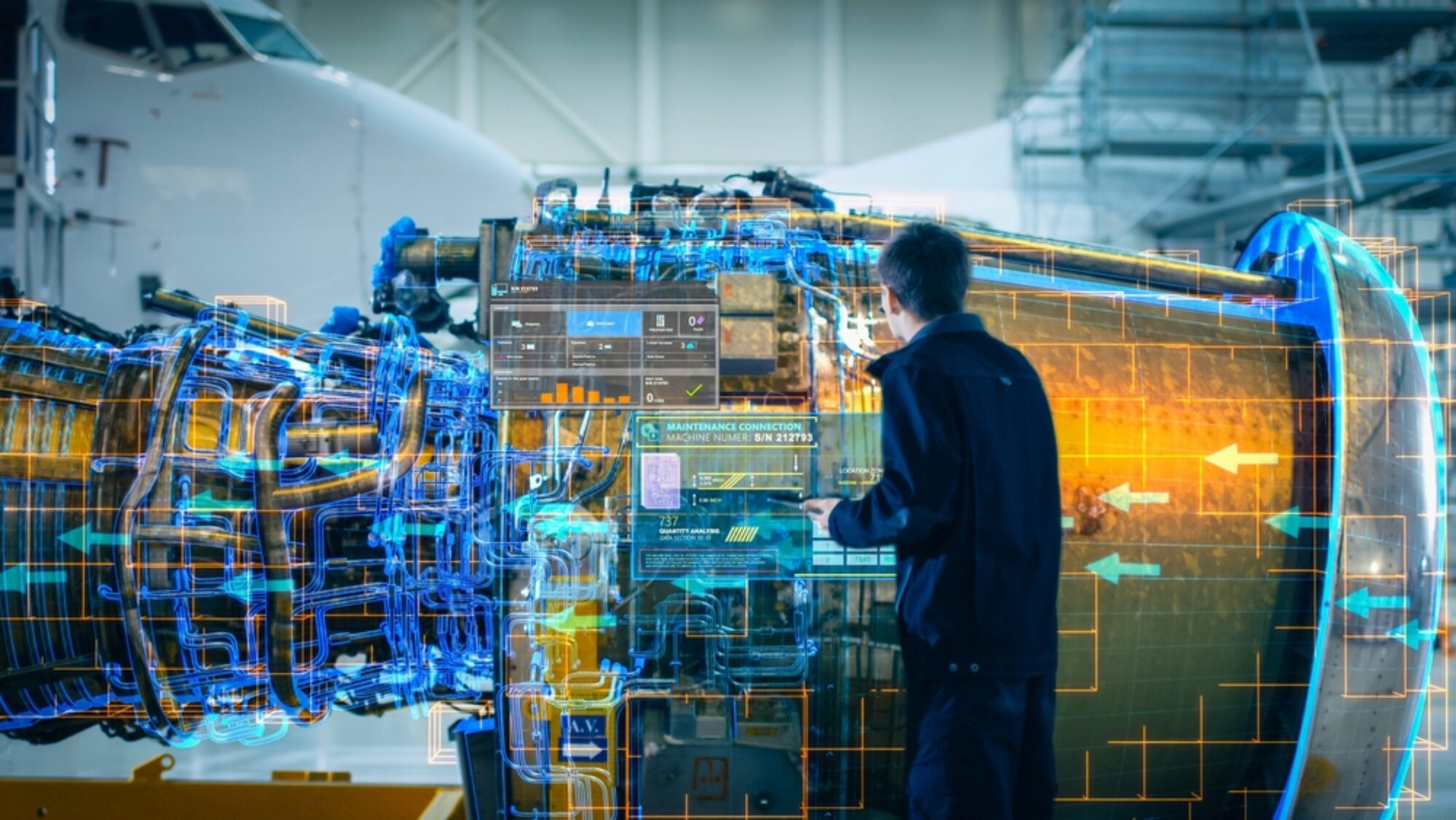

As their benefits become clear, digital twins have become both an accepted industry buzzword and a government priority. In partnership with BEIS (now DSIT), Digital Catapult recently led a consultation on cyber-physical infrastructure, and are looking forward to the launch of a new national digital twin programme: the Design Smarter Digital Twin Centre (DCSTC) in Belfast. This will help UK business compete in the global market and lead to a broad range of direct commercial benefits, including:

- Reducing the time to market and cost for production design

- Reducing consumption of energy and materials

- Improving the management of assets in real time

- Increasing productivity and competitiveness

As part of this initiative, we brought together a group of UK industry leaders to discuss the case for investment in digital twins and how to accelerate their adoption at scale. The session began with a presentation by Iain Percy OBE, double Olympic sailing gold-medallist and CEO of Artemis Technologies, a specialist in green maritime technology and founding partner of the Centre.

The Artemis experience

Iain Percy is on a mission. Not in pursuit of another gold medal, but to decarbonise the maritime industry. His company is using digital twins to get there, partly because of his sailing experience: “When I competed for the America’s Cup I quickly realised that it was all about the machine – we humans were pretty irrelevant. However, the Cup rules say you can only build one boat and if you damage it on the water you lose a lot of time and money. So you build a digital twin – an expression of your global knowledge. You have to win the virtual race before you can even think about winning the real one.”

Artemis employs 120 people, designing and building a new generation of zero-emission vessels, but retains its startup feel. “Small is powerful because it helps you avoid silos,” says Iain. “We are always learning from each other – and from industries such as aerospace and automotive.

“Our success with digital twins is improving all the time and now we have built the world’s most advanced maritime simulator. It’s the expression of our digital toolchain – everything we know is in there, which means we always test our vessels virtually before they reach the sea.”

Iain shared his first-hand experience with the group. “Repeatability is a philosophy, so don’t design the digital toolchain to solve a specific problem. The fidelity varies, but that’s fine. You need something proprietary, but you can’t be an expert at everything: get to 80% and you can always leverage other technologies and skills. As you steadily move up the fidelity level it becomes a virtuous circle.

“One important impact of a digital twin is that it removes the noise – not only of the wind and waves, but also of people’s opinions. It normalises language and makes us think about what we’re saying. Successful teams build knowledge block by block; they don’t just challenge the answer without evidence.

“Of course digital models are always wrong: assumptions are where the real intelligence comes from, so we have to continually challenge these.”

Touching on another key issue, Iain noted that regulators’ lack of relevant experience can be an obstacle, but decided to focus on the positive: “We have a huge opportunity in the UK if we can get regulators to really understand digital twins and make the development process as fast as possible.”

Following Iain’s presentation, a lively and thoughtful group discussion revealed a number of key themes.

The complexities of collaboration

“The power of digital twins is that they talk to each other: collaboration is the key,” according to Iain – and the group members agreed. However, they also spoke of patchy progress, even within the same organisation, and the frustration of trying to reach contractual agreement between multiple parties. It’s complex, governance is a problem and sometimes legal departments just can’t find a way. Also, to realise their full potential, digital twins need to be distributed and interoperable. This means industry must understand what IP it can (and should) own.

The group discussed Iain’s point that the digital twin should enable the organisation to capture knowledge and challenge assumptions. They mentioned standards many times, but recognised that these are slow to develop and not adaptable. They also emphasised the need for a common language.

Change is coming

It’s particularly important to ensure that digital twins are not viewed as a technology issue or an IT project. They are living things, as intrinsic to the business as finance or HR, and potentially transformative. Which means we must get CFOs on board with the shift from capital to operational expenditure, and show other industry leaders how to articulate the non-financial value of digital twins.

For example, digital twins allow major engineering projects to be built without a traditional prototype. The first iteration of the physical asset may actually be the tenth, when you include its digital predecessors.

Progress requires industries to share business change stories and develop programmes that address the skills gap, both through external resourcing and internal development. It also requires investment. As a rule of thumb, the group estimated a minimum of 1% of the total budget for a physical project should be spent on digital twins.

Digital twins continue to contribute over the entire lifecycle of a project. Sensors and analysis allow components and materials to be reused, so product sales can become value-added services and manufacturers become recyclers. Construction projects resemble repeatable manufacturing processes, using standardised components and systems. However, this evolution requires a shift in mindset. Continuous evolution creates gaps and demands a culture of failing fast, learning, and capturing this new knowledge in digital twins and the assumptions they contain.

Wider value of digital twins

We are starting to see how this new way of working compels us to understand our data, where it comes from and how it interconnects with other models. For example, not only are digital twins fundamental to reaching NetZero targets, but they also play a major role in safety. A network of digital twins makes it easier to avoid service strikes; it takes people out of a construction site and into the safer factory environment. In turn this encourages a more diverse workforce and improves wellbeing.

We can even create digital twins of humans to simulate the customer or worker experience. Learning from elite sport and incorporating technologies such as motion-capture, we can create customised environments, and reduce accidents and bad practice.

As for investment, the industry group revealed that financial factors are the most important drivers. While the high level benefits are clear, it was still difficult to articulate them within the decision-making process. Repeatability and interoperability are key, and there is an opportunity to link digital twins to the P&L and deliver compound business value through the model. While far-reaching changes are needed, the potential rewards are enormous.

As for next steps, Digital Catapult is in the process of forming an industry advisory group for the DSCTC, to act as a working group on digital twin adoption.

To engage in further conversations on this topic, learn more about collaboration opportunities and connect with Digital Catapult, reach out to Nick Wright at [email protected]

Digital Catapult newsletter

Receive articles and insights like this delivered directly to your inbox

Subscribe now