Supporting successful solution development

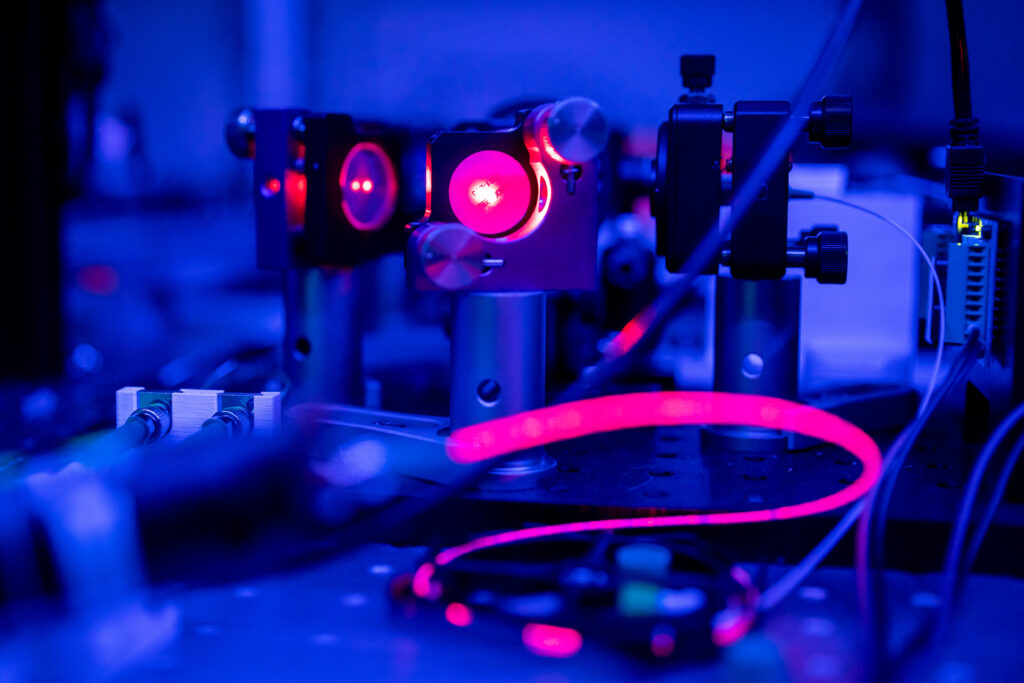

Instrumentation Technologies’ prototype solution included hardware, software, calibration procedures, wireless power and communication, data transfer, measurements, miniaturisation and housing design for harsh environments. It also required the use of specialised components at a time when supply chain difficulties were widespread. The Instrumentation Technologies team was able to leverage DigiFed’s ecosystem to obtain what they needed within a tight timeframe.

Both Instrumentation Technologies and Acciona draw on DigiFed’s diverse skills and expertise in innovation, engineering, evaluation methodologies, and project management. Digital Catapult’s project management approach provided a structured environment for monitoring progress and results, and both support teams provided objectivity and appropriate interventions to ensure that the perceptions and goals of both parties were aligned throughout the project. For example, we ensured that they both had the same vision and definition of what success looked like and helped them to identify the next steps required at a key stage during the project development.

The industrial prototype for monitoring the performance of the reverse osmosis membrane underwent testing and validation in lab environments and in a simplified and yet relevant industrial setting. It was found to successfully fulfil all Acciona’s required and desired criteria: enabling real-time digital assessment of reverse osmosis membrane and pressure vessel performance, identifying problematic membranes, and enabling integration of these measurements into active operational strategies.

About DigiFed

DigiFed is a network of innovation hubs across Europe that creates sustainable cross-border services and partnerships between small and large businesses, universities, public bodies and research and technology organisations. Digital Catapult is the UK hub.

DigiFed focuses on the adoption of cyber-physical systems (CPS) (especially by non-digital businesses) to transform and digitise their operations, products and service offerings. It establishes collaborations between prominent industry players and technology start-ups and SMEs, empowering innovators to penetrate new markets.