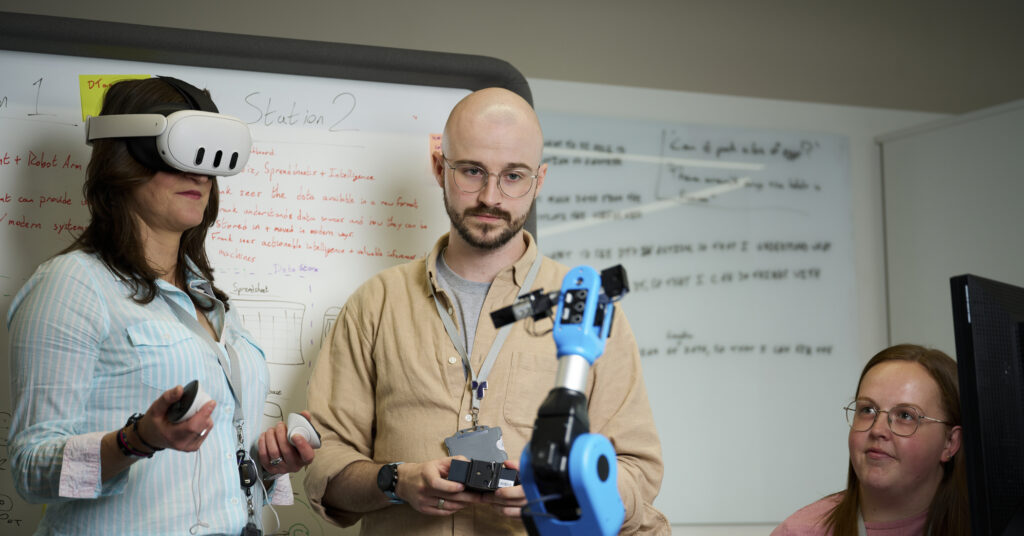

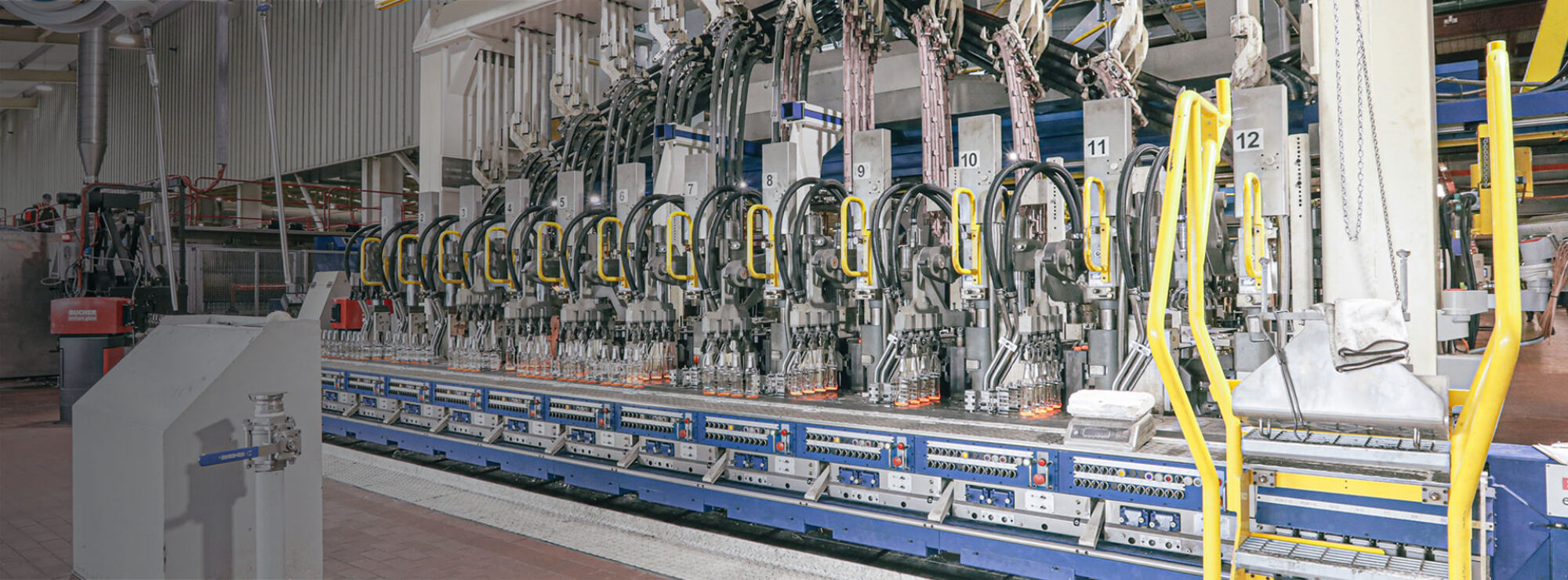

Since completing the Tenfold NetZero Accelerator Pilot Programme in November 2024, i3D robotics is demonstrating how a well-structured innovation challenge can lead to meaningful industrial progress. What began as a short-term proof of concept on the Digital Catapult-led programme has evolved into a live production trial at Encirc, a major UK glass manufacturer based in Northern Ireland, with the potential to revolutionise defect detection in one of the most energy-intensive industries.

Funded by the Department of Agriculture, Environment and Rural Affairs (DAERA) and delivered by Digital Catapult,

Tenfold NetZero supported three industry partners in Northern Ireland to tackle industrial decarbonisation challenges using advanced technologies. By connecting innovative deep tech SMEs with large industrial partners, Digital Catapult supported developing, testing and validating solutions that could help accelerate decarbonisation in the glass industry. For i3D robotics, it offered a rare opportunity to apply its inspection technology directly to the sustainability challenges of glass manufacturing.