- Two thirds of manufacturing leaders said they will focus on making their organisations’ supply chains more resilient in 2022

- Supply crises listed as main reason for manufacturers to innovate business models this year

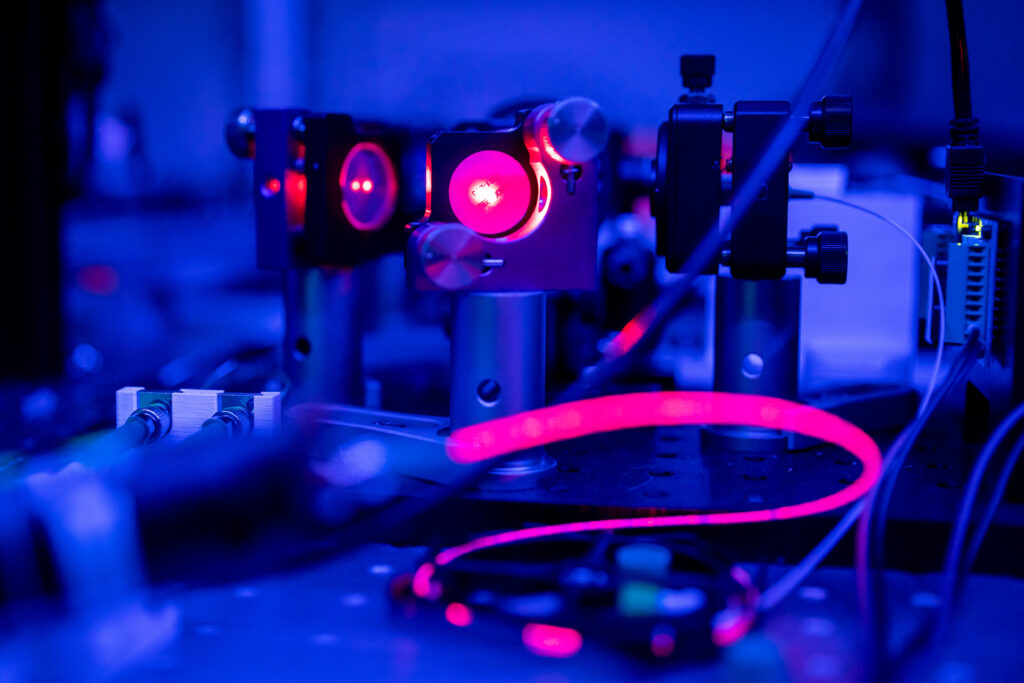

- Cloud, predictive analytics and Internet of Things are top tech investment priorities for manufacturers in next 12 months

Strengthening supply chains is a priority for nearly two thirds (64%) of manufacturing pros, according to research from Digital Catapult.

Manufacturers also set out their digital ambitions for the new year, as advanced digital technology quickly emerges as an answer to supply chain afflictions – including businesses grappling with parts and materials shortages, sudden factory shutdowns and unfinished products, and consumers facing long queues, late deliveries and even empty shelves.

Manufacturing leaders selected supply chain crises as the top reason why manufacturers need to innovate their business models in 2022, while over half (51%) said that building more data-driven supply chains was the greatest opportunity to make their organisation more resilient and sustainable over the next 12 months.

The results were collated as 2021 came to a close – a year which exposed shortcomings in global supply chains and the wide-reaching impact of continuous supply disruption rose to the fore.