Twelve manufacturers from across Northern Ireland who have been selected to embark on the FutureScope Smart Manufacturing Experiment programme had an unusual visitor for their opening session today – Spot, the robotic dog!

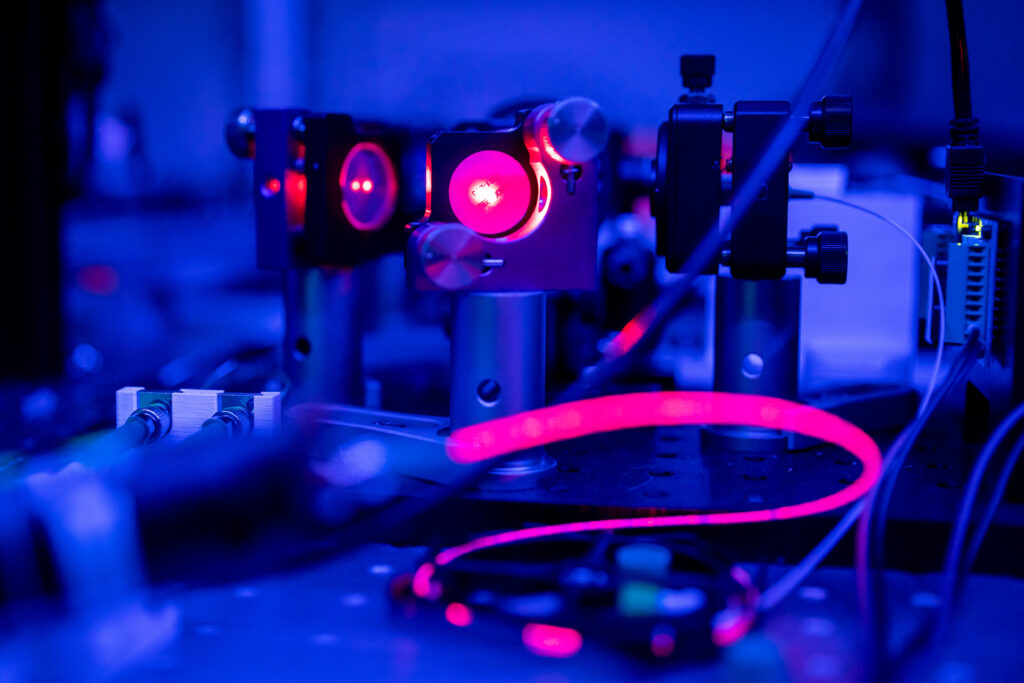

Created by Boston Dynamics, Spot was in attendance at the Ormeau Baths event to showcase the Leica BLK ARC, an autonomous laser scanning module for robots.

When integrated with robotic carriers, the BLK ARC enables autonomous mobile laser scanning with minimal or no human intervention. The combined technology can enable manufacturers to get a constantly updated 3D view of dangerous or difficult to reach sites and allows factories to be managed remotely, much more efficiently.

Delivered by Digital Catapult as part of the Smart Nano NI consortium, the new FutureScope Smart Manufacturing Experiment programme will see participating companies take part in a series of accessible learning sessions over 12 weeks. Local manufacturers will start to gain the necessary skills and knowledge to introduce the technologies, tools and techniques of Industry 4.0 in their workplace.