Digital Catapult has launched research into the impact of 5G on the UK’s manufacturing sector, uncovering the potential of 5G technology for industry and setting out recommendations for 5G to tackle connectivity challenges. With potential to contribute up to £15.7 billion per year to the UK economy by 2025, 5G will enable large scale business transformation if key barriers are overcome.

Made in 5G, created in partnership with Digital Catapult’s 5G in Manufacturing Working Group and drawing on new research direct from the UK’s manufacturing industries and 5G technology providers, outlines the main challenges to 5G adoption by industry, and sets out recommendations for the UK’s manufacturing industries and their supply chains.

An overwhelming majority of manufacturers surveyed for Made in 5G identified a lack of demonstrable return on investment (71%) as the main barrier to 5G adoption. Cost (56%), concerns around compatibility and interoperability of existing networks often due to problems with legacy solutions (20%), security concerns as manufacturers tend to prefer control over their own networks (32%), lack of understanding about 5G (42%), and cultural barriers to adoption such as skills (54%) were also identified as obstacles.

Jeremy Silver, CEO, Digital Catapult, said: “Made in 5G sets the wheels in motion for the journey towards Industrial 5G. It’s a long road, and as with all leading edge technologies, it is essential for manufacturers to engage early so as not to be left behind. There’s a real business case for getting skin in the 5G game right now, helping to shape the use cases for a technology which promises to be revolutionary for output and productivity across the UK’s manufacturing industries. Digital Catapult is perfectly positioned to guide manufacturers along that road to success.”

Innovation is crucial for the future of the UK’s manufacturing. 5G can address a wide range of use cases, from onsite processes to connected goods, and address concerns manufacturers have about cellular technologies for in-factory connectivity. It will also enable new business models and help manufacturers to deliver new services for their customers.

Juergen Maier, CBE CEO Siemens UK, Chairman, Digital Catapult & Made Smarter, said: “We need to empower ourselves with the knowledge of what 5G can deliver for us in real terms – and we need to take active steps to explore what this will mean for our businesses so that we don’t fall behind. Digital Catapult, as the UK’s leading innovation centre for advanced digital technology adoption by industry, can help us to do this.”

UK businesses can lead the world in the development of new applications and services to run on advanced digital networks. To achieve UK economic impact, innovation in 5G depends on access to infrastructure and expertise. The manufacturing sector needs to think proactively about the future of connectivity and 5G will play a crucial role in this growth journey. The potential of moving away from wired connectivity to 5G will increase mobility, flexibility and geographical range that could be game changing for many companies across the country.

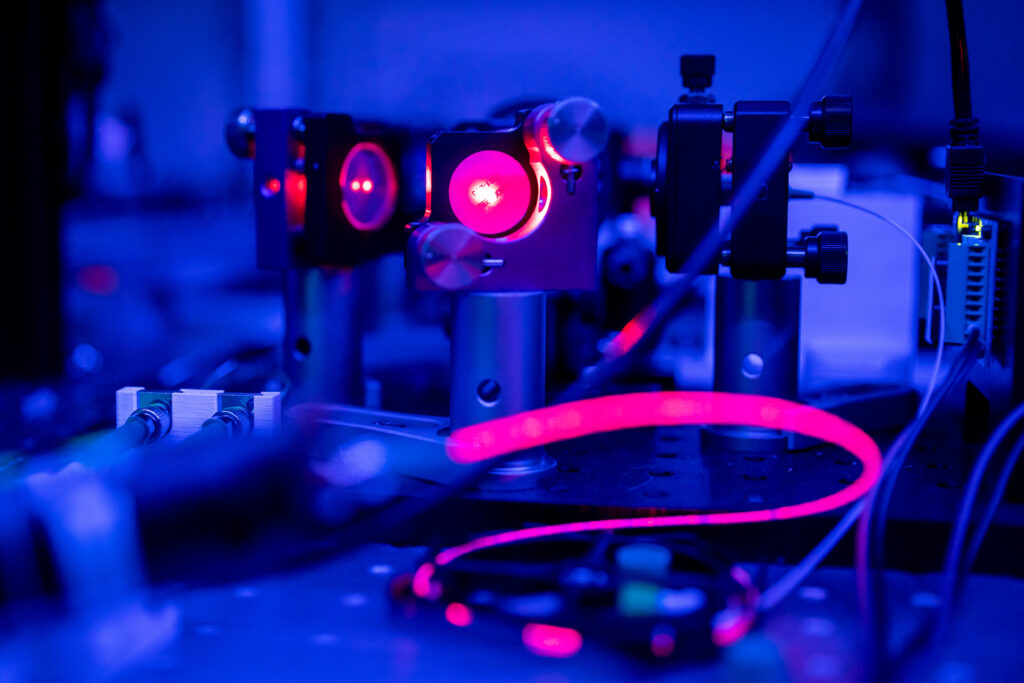

Digital Catapult is removing barriers to market and supports the growth of 5G in a number of ways. The Made in 5G discussion paper builds upon Digital Catapult’s unique record of furthering the development and adoption of 5G in the UK, including projects such as the 5G Testbed in Brighton and the launch of the UK’s first 5G enabled Immersive Lab at The Landing in Manchester.