Additive Flow

Additive Flow was established in 2017 by co-founders Alexander Pluke and Charles Fried to develop digital solutions for the additive manufacturing workflow – a need they identified when CEO Alexander Pluke designed a multi-material 3D printing machine, only to discover the software available was not fit for purpose.

Combining their backgrounds in data science, machine learning, generative design and additive manufacturing, Alexander and Charles created Additive Flow, with a mission to intelligently progress the capabilities of manufacturing, materials and design through optimisation for additive manufacturing and beyond.

From Additive Flow, Formflow was then born: an intuitive optimisation software that works by optimising material properties based on engineering and business relationships.

Balancing performance, sustainability and cost savings within the advanced manufacturing workflow.

Every engineering and production process has competing requirements, such as performance versus cost or reliability over speed or innovation.

While traditional software rarely considers these non-engineering values, by transforming the physical production process, Formflow can help to reduce costs, deliver productivity gains and increase sustainability.

“The massive impact of weight and moving heavy things around causes CO2 emissions. It’s also more expensive because you’re using materials inefficiently,” explained Alexander.

“We embed sustainability up front and centre with performance. If you bring in sustainability there, you can change the way the world works. We want to positively influence the innovators of this planet.” he added.

Unlocking the power of optimisation

Formflow is designed to meet the challenges faced by designers and engineers working with 3D printing and additive manufacturing processes – extending into mass manufacturing including injection moulding, casting and electronics.

“We come in when there’s an engineering concept, design or a manufacturing problem that needs to be solved. These are physical components in the real world that need to do a job,” said Alexander Pluke, co-founder and CEO of Additive Flow.

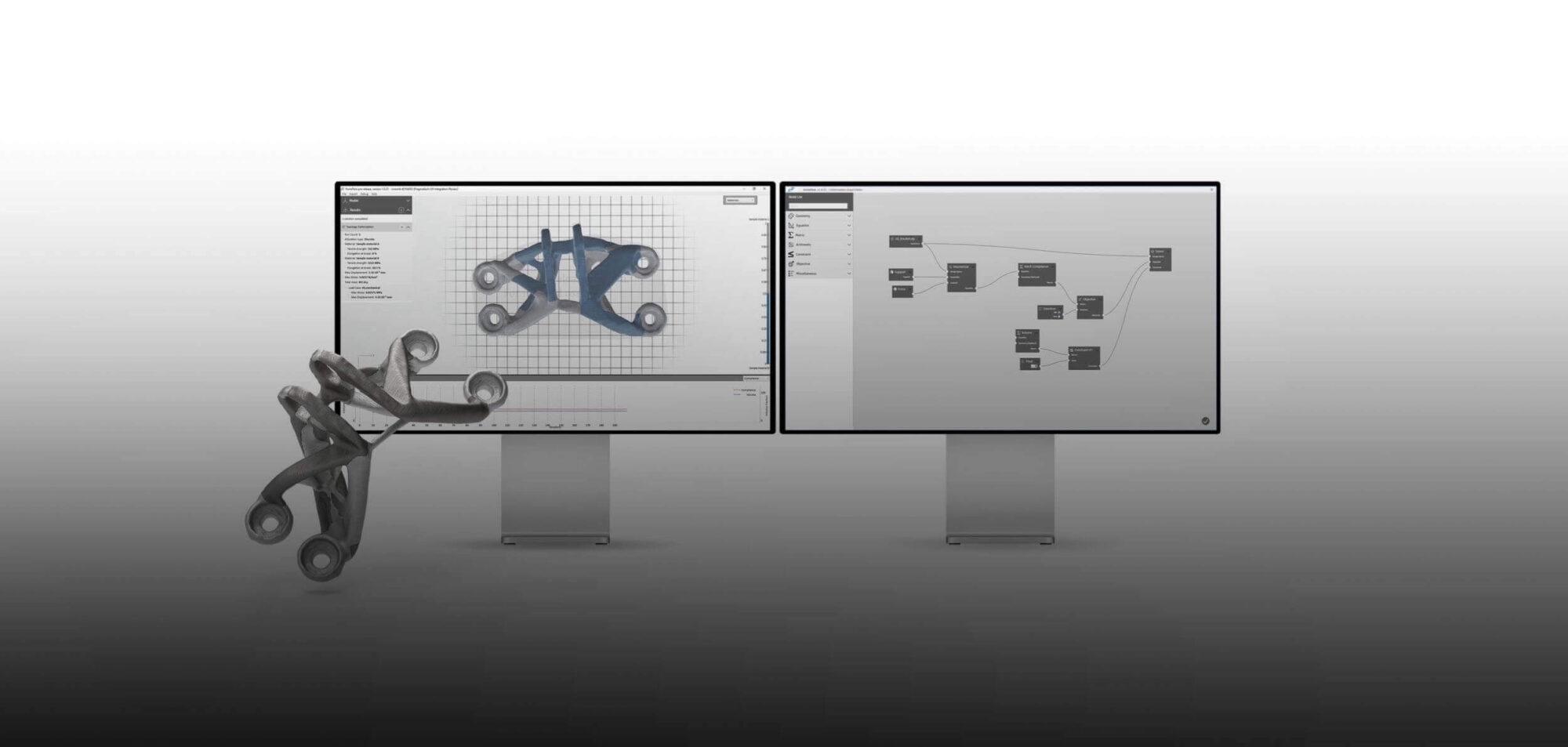

Formflow provides an interactive framework, enabling users to define a multitude of project specifications, including the design space, geometries, materials and boundary conditions, while considering any physical requirements, such as strength, load or thermal conditions on the whole or individual parts.

With leading optimisation algorithms, Formflow generates a series of different solutions based on the manufacturing process and material properties selected.

Additive Flow joins Machine Intelligence Garage to advance the performance of its technology.

In 2019 Additive Flow joined Machine Intelligence Garage, Digital Catapult’s flagship acceleration programme for artificial intelligence (AI) and machine learning (ML) startups.

For Additive Flow, Machine Intelligence Garage offered the technical support and computational power needed to advance its technology, including access to one of the UK’s most powerful supercomputers located in the University of Edinburgh (EPCC).

“We joined Machine Intelligence Garage for the expertise element, helping us to take and deploy data within high-performance computing environments,” said Alexander.

“In Edinburgh, we used one of the fastest supercomputers in the world, which allowed us to augment our datasets and push our optimisation to its limits. We’ve got really efficient algorithms, and when we’ve benchmarked ourselves against other simulation tools, we are sometimes four-to-five-times faster, but there were so many more parameters we can look at.”

“With access to that supercomputer and the support community within Machine Intelligence Garage, the algorithms we’ve now developed have increased our performance and production capabilities.”

Digital Catapult is committed to discovering new ways of solving industry challenges, increasing productivity and opening global markets for UK companies. In early 2020 Additive Flow also took part in the UK-Germany global challenge, arranged by Digital Catapult for multinational companies Siemens and CHEP Europe.

In 2020, the Mayor of London commissioned Digital Catapult to advise on technology research and innovation trends over the next 15 years. In its report, Digital Catapult identified Additive Flow as one of the Top 10 London-based advanced digital technology innovators to watch in 2020.

Machine Intelligence Garage also provides valuable networking opportunities throughout each cohort, as startups share their journey as innovators and foster collaborations. During the programme, the Additive Flow team met with fellow AI founders from Photogram, who later worked with Formflow technology to develop their Alice Camera.

Creating the software to change our world physically.

For Additive Flow, as interest in its technology grows, the company is gaining pace, developing its business with manufacturing materials organisations and large internationals such as Saint-Gobain and DSM.

Looking to the future, Additive Flow continues to innovate, planning to revolutionise industrial engineering and deliver sustainability across many sectors, including automotive, medical and aerospace.

“Our strategy is made up of a mix of cloud-based and local computing power,” said Alexander Pluke.

“We’re excited by the GPU acceleration we’ve done within our system and have solvers that can handle advanced work hyper-efficiently, even on a laptop. So we’ve got computers that can do advanced work with really efficient algorithms.

“Additive Flow is unique, in that we are using software to interact with the real world and make physical objects considering multiple levels. That’s something very powerful, because you can see the impact and change the world physically.”